It’s amazing how much technology, gadgets, memory sticks, wires, and batteries we use these days. The manufacturing of these devices and the use of rare materials that go into their production represent a huge source of energy we take from the earth.

E-Waste- The Introduction!

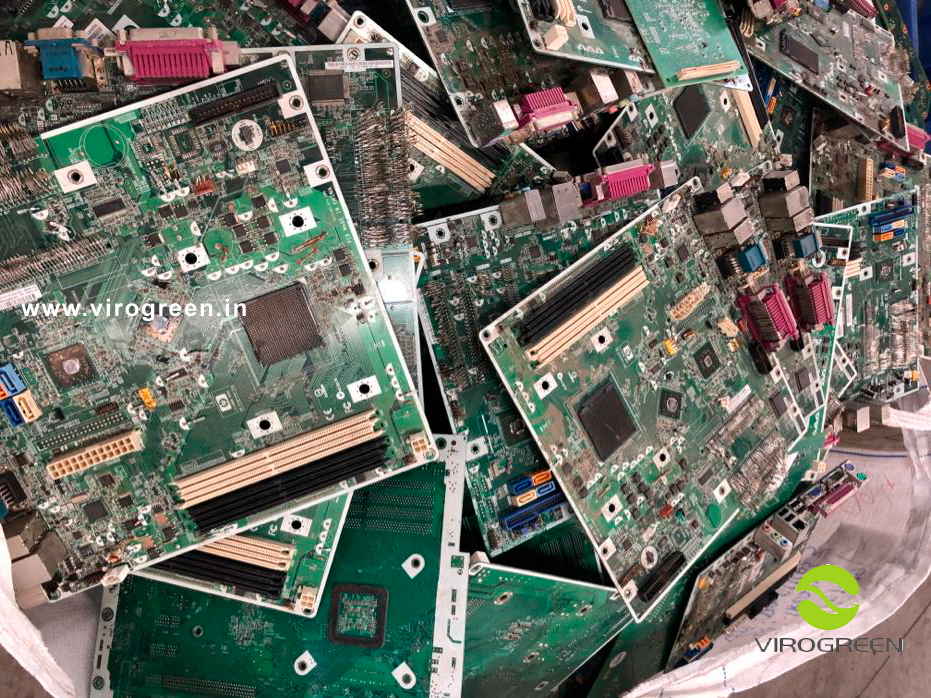

E-Waste is anaccepted, informal name for electronic products nearing the end of their useful life. E-Wastes are considered dangerous, as certain components of some electronic products contain materials that are hazardous, as certain components of some electronic products contain materials that are hazardous, depending on their state as well as density.

The hazardous content of these materials pose devour to human health and environment. Leftover Computers

- Laptops

- Servers

- IT waste

- fax machines

- House hold Ewaste

- cell phones

- audio equipment

as well as batteries if improperly disposed can leach lead as well as other substances into soil and groundwater. Numerous of these products can be reused, or recycled in an environmentally sound approach so that they are less harmful to the ecosystem.

Management of E-Wastes

It is estimated that seventy-five percent of electronic items are stored due to uncertainty of how to manage it. These electronics junks lie unintended in houses, offices, warehouses, etc. and usually mixed with household wastes, which are finally disposed off at landfills. This necessities implementable management measures!

In industries management of e-waste should start at the point of cohort. This can be done by waste minimization techniques as well as by sustainable product design. Virogreen is the leading e-waste management company in India that provides premium e-waste recycling solutions. E Waste minimization in industries involves adopting:

- Inventory management

- Production-process modification

- Volume reduction

- Recovery and reuse

Inventory Management

Proper control over the materials used in the manufacturing process is an imperative method to reduce waste generation. By plummeting both the quantity of perilous materials used in process and the amount of excess raw materials in stock, the quantity of waste generated can be reduced. This can be done in two ways i.e. establishing material-purchase review as well as manage procedures and inventory tracking systems.

Production-process modification

Changes can be made in the production procedure, which will diminish waste generation. This lessening can be achieved by changing the materials used to make the product or else by the more efficient use of input materials in the production process or lack procedure and examination of the production process for ways to improve its efficiency.

Volume Reduction

Volume reduction encompasses those methods that remove the hazardous portion of a waste from a non-hazardous portion. These techniques are usually to diminish the volume, and thus the cost of disposing of a waste material.

Recovery and Reuse

This method could eliminate e waste disposal costs, reduce raw material costs as well as provide income from a saleable E waste. E Waste disposal can be improved on-site, or at an off-site revival facility, or through inter industry exchange.